How to Hire a Woodworking Machine Operator in Canada?

As proficient woodworking machine operators bring proficiency, consistency, and efficiency to your woodworking projects, hiring a skilled woodworking machine operator can significantly enhance your industry’s productivity by harnessing their artistic flair, technical expertise, and dedication to meticulous workmanship.

However, head-hunting such professionals is no mean feat, as it demands an extensive network within the Canadian woodworking industry. As a specialized recruitment agency, Hookjobs is unwaveringly committed to managing the hiring process of top-talent woodworking machine operators.

How we Help you Hire a Woodworking Machine Operator in Canada?

By offering certain employment services, our recruiters at Hookjobs ensure you hire the most skilled woodworking machine operators. Hookjobs’ assistance includes streamlining the hiring process, having access to a pool of pre-screened candidates, expertise in finding the right fit, and seamlessly handling administrative tasks.

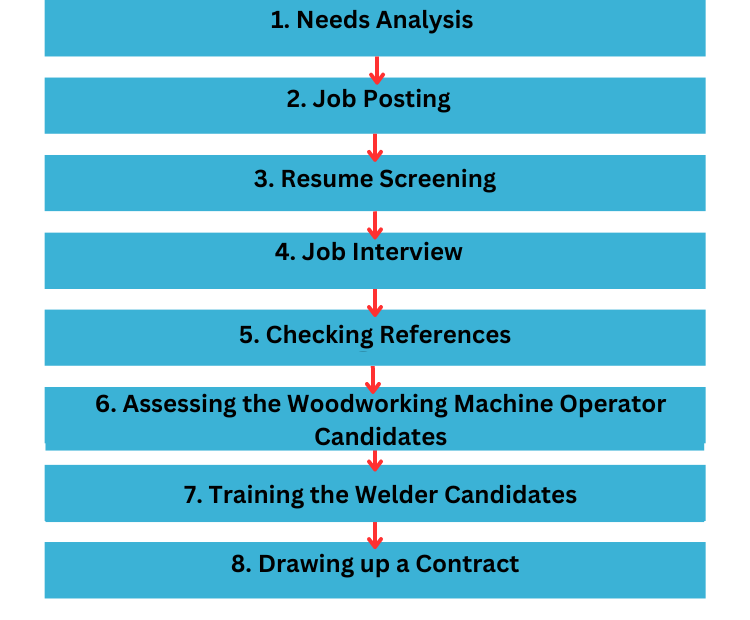

Below is a visual recap of the typical stages we follow to onboard a skilled woodworking machine operator for your woodworking enterprise in Canada:

1. Needs Analysis

At Hookjobs, we are dedicated to aligning the recruitment process with your woodworking machine operator requirements. Our approach goes beyond just locating skilled professionals – we ensure their compatibility with your unique vision for woodworking projects in Canada. To achieve this, we meticulously examine your needs, tailoring our strategies to your woodworking staffing necessities.

Our process commences with creating a comprehensive inception report encompassing every facet of the woodworking machine operator role. This report serves as a foundational plan, detailing the precise attributes, qualifications, and traits you desire in the operators you plan to onboard.

Here are some essential factors we consider when conducting a needs analysis before hiring a woodworking machine operator:

- Understanding your woodworking projects: Understanding the details of your projects is vital, as candidates who are well-versed in the specifics of your woodworking projects can seamlessly integrate their skills. For instance, a candidate with experience in intricate furniture design can excel in crafting detailed pieces, while someone with a background in diverse projects can adapt to various scales and styles. This understanding ensures precise, tailored outcomes aligning with your vision and quality standards.

- Technical proficiency: We closely examine the specific technical skills essential for the woodworking machinery and equipment integral to your projects. This entails evaluating candidates’ proficiency in operating specialized tools, achieving precision cuts, and executing intricate woodworking tasks.

- Machine expertise: Understanding the precise types of machinery and equipment prevalent in your operations is paramount. We look for candidates based on their experience and familiarity with the specific machines crucial for your woodworking projects.

- Safety emphasis: Given the inherent risks in woodworking, safety is paramount. We prioritize candidates who are strongly committed to safety protocols, safeguarding themselves, their colleagues, and your work environment.

- Material knowledge: Different wood types necessitate distinct techniques. We evaluate candidates’ understanding of various wood materials and their aptitude for tailoring techniques based on the characteristics of different woods utilized in your business.

- Language skills: Cooperation with colleagues holds paramount importance in woodworking machine operation. It’s essential to ensure prospective machine operators can communicate seamlessly with their colleagues, fostering an interactive atmosphere. Hence, if your business involves international workers, we prioritize language skills during the assessment process.

- Timelines and deadlines: We consider your specified project timeline and ensure the woodworking machine operator’s availability aligns with your schedule.

2. Job Posting

Crafting a well-designed job posting that attracts a pool of talent is essential to hooking a high-quality woodworking machine operator.

Creating tailored job postings based on the specific demands of your business, Hookjobs taps into various social media platforms to ensure the attraction of qualified woodworking machine operators.

Here’s an example of how we post your vacancy for the woodworking machine operator position:

Job Title: Woodworking Machine Operator

Location: Canada

- Job Description:

Are you a skilled and dedicated woodworking machine operator ready to play a pivotal role in the world of woodworking and manufacturing? We are a renowned wood manufacturing company operating in Canada, and we’re actively seeking a talented woodworking machine operator to join our team in Toronto, Ontario. As a woodworking machine operator, you’ll have the exciting opportunity to utilize your expertise in operating woodworking machinery to create precision-crafted components that contribute to exceptional woodworking projects.

- Responsibilities:

- Demonstrating mastery in woodworking machine operation, including setting up and adjusting machines, loading raw materials, and monitoring machine performance to ensure accurate and high-quality output.

- Operating various woodworking machinery, such as saws, routers, planers, and lathes, to shape and cut materials according to specified measurements and designs.

- Collaborating closely with production supervisors and designers to interpret technical drawings and ensure precise execution of woodworking projects.

- Applying innovative techniques and processes to optimize machine operation and enhance efficiency in producing intricate wood components for furniture and structures.

- Upholding stringent quality control measures, inspecting finished components to verify they meet or exceed industry standards, and making adjustments as needed.

- Managing work schedules efficiently to meet production timelines and contribute to a smooth manufacturing process.

- Approaching technical challenges with a proactive problem-solving mindset and seeking continuous improvement in machine operation.

- Staying up-to-date with industry trends, technological advancements, and emerging woodworking techniques to enhance the quality of production processes.

- Requirements:

- Proven experience as a woodworking machine operator, supported by a diverse portfolio showcasing your proficiency in operating various woodworking machinery to create precise components.

- In-depth knowledge of woodworking equipment, materials, and safety protocols to ensure safe and efficient machine operation.

- Effective communication skills to collaborate with team members and interpret technical drawings accurately.

- Ability to work independently and as part of a team, demonstrating adaptability across different projects and contributing to a cooperative work environment.

- Commitment to adhering to safety regulations and maintaining a clean, organized workspace.

- Eligibility to work in Canada and any relevant certifications or licenses for woodworking machine operation.

If you’re a dedicated and adept woodworking machine operator looking to elevate your career in woodworking and manufacturing, we encourage you to submit your application. Join our team of professionals, contributing your technical expertise and precision skills to a manufacturing company that values accuracy, innovation, and the art of crafting impeccable woodworking components. Apply now and let your skills shine!

3. Resume Screening

To expedite the selection process and identify top-talent woodworking machine operator candidates, our recruiters at Hookjobs thoroughly review and evaluate the submitted resumes.

Our priority is to verify if the woodworking machine operator candidates hold the necessary certificates or diplomas in the woodworking industry in Canada. This aids us in ensuring that the candidates can perform the job professionally and comply with legal requirements.

Some of the essential woodworking machine operation certifications in Canada are as follows:

- Woodworking Machine Operator Certificate: Offered by various vocational schools and trade organizations, this certification validates an individual’s proficiency in operating different woodworking machinery and adhering to safety protocols.

- Occupational Health and Safety (OH&S) Certification: While not specific to woodworking, this certification emphasizes workplace safety, which is critical for woodworking machine operators to prevent accidents and injuries.

- CNC Machine Operator Certification: For woodworking operations involving Computer Numerical Control (CNC) machinery, this certification demonstrates expertise in programming, setting up, and operating CNC machines for precision woodworking tasks.

- Workplace Hazardous Materials Information System (WHMIS): This certification ensures operators understand the hazards associated with materials used in woodworking and how to handle, store, and dispose of them safely.

- First Aid and CPR Certification: Though not woodworking-specific, having certified operators with first aid and CPR skills can enhance workplace safety in case of emergencies.

- Woodworking Tool and Equipment Safety Certification: Focuses on the safe operation and maintenance of various woodworking tools, ensuring operators can identify potential hazards and mitigate risks.

- Apprenticeship Completion: Completing a recognized apprenticeship program in woodworking can lead to a certification that demonstrating a comprehensive understanding of woodworking techniques and machinery operation.

- Manufacturer-Specific Training: Machinery manufacturers often provide training programs that certify operators on the safe and efficient operation of their specific woodworking equipment.

Also, different provinces of Canada may require their own specific certifications, some of which are illustrated in the following table:

Province / Territory | Potential Woodworking Certificates / Programs |

Alberta | – Alberta Apprenticeship and Industry Training: Woodworking Machinery Operator Certification |

British Columbia | – BCIT (British Columbia Institute of Technology) woodworking and joinery programs |

New Brunswick | – New Brunswick Community College (NBCC) woodworking programs |

Newfoundland and Labrador | – College of the North Atlantic woodworking-related programs |

Nova Scotia | |

Ontario | – Various colleges like Conestoga College and Centennial College offer woodworking programs |

Quebec | – Various CEGEPs offer woodworking programs |

Saskatchewan |

Besides the mentioned certifications, we ensure the woodworking machine operators possess the following pivotal criteria as well:

We carefully examine the woodworking machine operator candidates’ submitted portfolios to assess the quality and diversity of their past woodworking projects. This allows us to gauge their skill level, attention to detail, mechanical flair, and ability to handle various materials, providing a visual representation of their craftsmanship.

Relevant experience is valued in our selection process. We review the applicants’ resumes to identify woodworking-related roles and responsibilities, assessing their familiarity with operating machinery, executing precise cuts, and managing projects that demand woodworking expertise.

Safety awareness is a priority in woodworking operations. In the resume screening, we look for indications that candidates are well-versed in safety protocols and practices within woodworking environments, ensuring the creation of a secure workspace for themselves and their colleagues.

Accurate measurements and calculations are integral to woodworking. During the resume review, we consider candidates’ mathematical proficiency by looking for indications of their ability to work with measurements, perform calculations, and follow dimensional specifications. Any experience involving precise measurements, use of mathematical tools, or attention to numerical details is noted as a positive attribute.

Effective communication is vital for safety and teamwork. During the resume review, we consider candidates’ language proficiency, looking for clear indications that they can understand and convey instructions accurately, especially regarding critical safety information and shop floor coordination.

Woodworking involves physically demanding tasks. In the resume review, we assess the woodworking machine operators’ physical readiness to handle role’s demands by looking for experiences that showcase their ability to stand for extended periods, lift heavy materials, and engage in repetitive tasks without compromising accuracy or quality. Any relevant physical skills or accomplishments are taken into account.

4. Job Interview

After the resume screening stage, we invite the woodworking machine operators to participate in a vis-à-vis interview with our professional recruiters. This interview allows us to gauge their skills and qualifications more accurately as top-notch woodworking machine operators.

Some of the questions we typically ask when hiring woodworking machine operators are as follows:

- General Questions:

- Tell me about your experience working with woodworking machinery and tools.

- What aspects of woodworking do you find most rewarding and enjoyable?

- How do you prioritize safety in a woodworking environment? Can you provide specific examples?

- Describe a project you worked on that required collaboration with other team members. How did you ensure effective communication?

- Can you share an instance where you had to adapt to changes in a woodworking project? How did you handle it?

- What steps do you take to maintain a clean and organized work area?

- Have you ever faced a challenging deadline for a woodworking project? How did you manage your time to meet it?

- What do you enjoy most about working with different types of wood and materials?

- How do you stay updated with new woodworking techniques and technology advancements?

- Can you share a situation where you had to troubleshoot a problem during a woodworking task? How did you resolve it?

- Technical Questions:

- Can you list the types of woodworking machines you have operated and your level of proficiency with each?

- Explain the process of setting up and calibrating a table saw for precise cuts.

- How do you determine the appropriate feed rate when using a planer or jointer?

- Describe the safety precautions you take when operating a router or spindle moulder.

- Have you worked with CNC woodworking machines? How do you program and operate them effectively?

- What are some common issues you’ve encountered while using a bandsaw, and how did you address them?

- Can you discuss the differences in tool selection and cutting techniques for hardwoods versus softwoods?

- How do you ensure accurate measurements and consistent dimensions throughout a woodworking project?

- Explain the steps you prevent tear-out and ensure a smooth finish when working with delicate or brittle wood.

- Have you used specialized jigs or fixtures to enhance your woodworking tasks? Can you provide an example of their application?

5. Checking References

Gathering further information about the woodworking machine operator candidates’ work history, skills, and professional conduct, Hookjobs finds the reference-checking stage an integral part of the hiring process.

Here’s how we typically approach reference-checking for hiring a concrete finisher:

- Contacting relevant references: We contact the references provided by the woodworking machine operator candidates. These references should be individuals who have directly supervised or worked closely with the candidate in previous woodworking-related roles. This might include supervisors, team leads, or colleagues who can provide insights into the candidate’s performance as a woodworking machine operator.

- Evaluating technical proficiency: Our recruiters evaluate the candidate’s technical skills as a woodworking machine operator during the reference-checking process. We ask the references about the candidate’s ability to operate different types of woodworking machinery, their familiarity with specific tools and equipment, and their accuracy in executing cuts and measurements.

- Assessing safety consciousness: Safety is paramount in woodworking. Hookjobs seeks to understand how safety-conscious the candidate is by asking the references about their adherence to safety protocols, their approach to maintaining a safe work environment, and any instances where they demonstrated exceptional safety awareness.

- Verifying work quality: We ask the references about the quality of the candidate’s work. This includes their attention to detail, ability to produce precise cuts and measurements, and overall craftsmanship in woodworking projects. Any feedback on the accuracy and consistency of their work is considered.

- Exploring adaptability: Woodworking projects can vary in complexity and material. We inquire about the candidate’s adaptability by asking the references if the candidate effectively handled diverse projects, materials, and tools. This provides insight into the candidate’s versatility as a woodworking machine operator.

- Team collaboration and communication: We ask the references to share observations about the candidate’s ability to work within a team of woodworkers. This includes their communication skills, willingness to share knowledge and insights, and teamwork in a collaborative woodworking environment.

- Attention to machinery maintenance: Keeping woodworking machinery in good condition is crucial. We seek feedback on whether the candidate actively maintained and cared for the machinery they operated. This could include routine maintenance, cleanliness, and reporting any issues promptly.

- Addressing challenges: We also encourage the references to share any challenges the candidate faced in their previous woodworking roles and how they tackled them. This sheds light on the candidate’s problem-solving skills and resilience in the face of woodworking-related difficulties.

- Verifying qualifications: We ask the references to verify the candidate’s listed qualifications and work history, ensuring that the information in the resume aligns with their experiences as a woodworking machine operator.

- Overall recommendation: After the reference discussion, we ask the references to provide an overall recommendation based on their experience working with the candidate. This recommendation could highlight the candidate’s strengths, areas of improvement, and suitability for the woodworking machine operator role.

- Reporting the results: We finally prepare a comprehensive report of the recorded information gathered from the references and share it with you.

6. Assessing the Woodworking Machine Operator Candidates

After checking references, we assess the woodworking machine operator applicants’ skills in real-world scenarios. To comprehensively gauge their woodworking skills while using machine operations, we administer the following assessments:

- General learning ability: We evaluate the woodworking machine operator applicants’ aptitude to quickly grasp new information, learn from experiences, and adapt their knowledge effectively. This trait is vital in a dynamic woodworking environment where new techniques and equipment may be introduced.

- Verbal ability: Their verbal communication skills are examined to ensure they understand instructions, communicate clearly with team members, and seek clarification when needed. Effective verbal communication contributes to seamless workflow and safety in the workshop.

- Numerical ability: We assess the candidates’ numerical proficiency as precise measurements and calculations are central to woodworking accuracy. A strong numerical ability ensures they can interpret plans, execute cuts, and produce high-quality work.

- Spatial perception: We also evaluate the machine operators’ capability to visualize and manipulate objects in three-dimensional space. Spatial perception is essential for accurately conceptualizing and creating complex woodworking projects.

- Form perception: We evaluate the candidates’ ability to recognize shapes and forms accurately. This skill is crucial for tasks such as fitting components together, ensuring seamless joints, and creating aesthetically pleasing woodworking pieces.

- Clerical perception: We also test the operators’ attention to detail in identifying object similarities and differences. Clerical perception ensures they can notice subtle variations in wood grain, texture, and other visual attributes that affect the quality of the final product.

- Motor coordination: We assess the candidates’ ability to synchronize their physical movements with visual information. Strong motor coordination guarantees precision when handling tools and operating woodworking machinery.

- Finger dexterity: We examine the operators’ fine motor skills and finger dexterity. This skill is crucial for handling small components, delicate tasks, and intricate detailing during woodworking projects.

- Attention to detail: We also assess the candidates’ capacity to maintain meticulous attention to every aspect of their work. Attention to detail ensures that their woodworking projects meet the highest standards in terms of accuracy, aesthetics, and functionality.

7. Training the Woodworking Machine Operator

After evaluating the potential woodworking machine operators, we select the accepted ones for further training. By offering tailored training programs, we ensure that your future woodworking machine operators are fully equipped with the necessary skills to cater to your business’s unique needs.

Our trainers at Hookjobs train the woodworking machine operator candidates while focusing on the following techniques:

- Customized company-specific requirements: We understand that every woodworking business has its unique processes and standards. Our training considers your specific requirements, whether it’s specialized product lines, preferred techniques, or specific quality benchmarks. We train the candidates to align their skills with your business’s distinct needs, ensuring they can seamlessly integrate into your operations.

- Advanced equipment and technology: Woodworking is evolving with advanced machinery and technology. Our trainers familiarize the prospective woodworking machine operators with the latest equipment and technology relevant to your business. They learn how to operate advanced woodworking machinery, software, and tools to stay competitive and efficient in today’s woodworking landscape.

- Quality assurance and company values: Customized training allows us to instill your company’s values and commitment to quality into candidates from the outset. They learn about the importance of adhering to your business’s quality standards contributing to your brand’s reputation in the industry.

- Workflow efficiency: Efficient workflow is crucial in woodworking operations. We educate the operators on organizing their tasks, optimizing time management, and maintaining a productive pace throughout the project.

- Team collaboration: As working effectively in a woodworking team is essential, we train the candidates on developing communication skills and collaborating with colleagues for seamless project execution.

8. Drawing up a Contract

The last stage of our hiring process involves creating a contract with the chosen woodworking machine operator candidates. This involves working closely with our legal experts to clearly define the terms and requirements of the job conditions.

Here are some steps we consider when drawing up a contract with the prospective woodworking machine operators:

- Job responsibilities and scope: We specify the woodworking tasks and responsibilities that the operator will be responsible for. This includes details about operating specific machinery, executing different woodworking techniques, and producing quality products.

- Work schedule and hours: We outline the expected work hours, including any shifts or flexible arrangements. Additionally, we clarify any overtime expectations or requirements based on the nature of the woodworking projects.

- Compensation and benefits: We clearly state the compensation package, including wages, bonuses, and any benefits such as health insurance or retirement plans that the woodworking machine operator will be entitled to.

- Safety and training: Safety is paramount in woodworking. We detail safety protocols, training requirements, and any certifications needed to ensure the operator’s well-being and compliance with regulations.

- Equipment and tools: We specify the equipment, tools, and machinery the operator will have access to. This includes any specialized tools or technologies relevant to the woodworking tasks.

- Quality standards and performance metrics: We outline the quality benchmarks the operator is expected to meet, such as accurate cuts, precise measurements, and overall craftsmanship. Clear performance metrics ensure consistent output.

- Materials and inventory: If applicable, we detail how materials and inventory management are handled. This includes responsibilities related to ordering, tracking, and using materials efficiently.

- Reporting and communication: We define reporting structures and communication channels. This ensures that the operator is aligned with team members, supervisors, and management for effective collaboration.

- Confidentiality and intellectual property: If relevant, we address confidentiality agreements and the protection of intellectual property, especially in cases involving proprietary designs or techniques.

- Termination and exit procedures: We outline the conditions under which the contract may be terminated, including notice periods and any severance arrangements. This provides clarity for both parties in the event of a contract conclusion.

- Arbitration and dispute resolution: We may also include a section on how disputes or disagreements will be resolved, which can involve arbitration or mediation processes.

- Legal compliance: Our legal experts ensure the contract adheres to relevant employment laws, regulations, and industry standards applicable to woodworking machine operator roles.

Labour Laws and Regulations for Hiring a Woodworking Machine Operator in Canada

Hiring a woodworking machine operator in Canada involves adhering to various labour laws and regulations to ensure fair and compliant employment practices.

Here are some key aspects to consider:

- Prioritize safety training and certification: Ensure all woodworking machine operators have the necessary training and certifications to operate machinery safely. Safety should be a non-negotiable priority.

- Thoroughly train for machinery safety: Provide comprehensive training on safety protocols and equipment usage. Uphold Occupational Health and Safety (OH&S) regulations to prevent accidents and ensure operator well-being.

- Understand age restrictions for machinery: Familiarize yourself with age restrictions for woodworking machinery. Adhere strictly to the minimum legal operating age to ensure compliance with child labour laws.

- Equip with proper personal protective gear: Supply appropriate personal protective equipment – goggles, gloves, and hearing protection – as mandated by OH&S regulations. Protect your operators’ well-being.

- Maintain comprehensive training records: Keep meticulous records of training provided to woodworking machine operators. These records serve as evidence of compliance during workplace inspections.

- Adhere to work hour regulations: Respect and comply with labour laws determining the maximum hours woodworking machine operators can work in a day or week.

- Honour overtime pay requirements: If operators work beyond standard hours, ensure adherence to overtime pay regulations. Uphold fair compensation practices.

- Create a respectful workplace: Establish policies that prevent workplace harassment and discrimination. Foster a safe and respectful environment for all woodworking machine operators.

- Accommodate physical demands and disabilities: Anticipate the physical demands of woodworking machinery. Be ready to accommodate operators with disabilities to promote inclusivity.

- Form a health and safety committee: Where required, establish a joint health and safety committee. Engage in proactive safety discussions and compliance efforts.

- Promptly report incidents: In the event of accidents or incidents involving machine operators, promptly report to the relevant authorities as per OH&S regulations.

- Regularly update safety policies: Stay abreast of safety regulations. Periodically review and update safety policies and training materials to align with the latest standards.

- Maintain accurate documentation: Keep detailed records of training, equipment maintenance, and incident reports. Document compliance for legal and safety purposes.

What is the Average Wage for Hiring a Woodworking Machine Operator in Canada?

The average wage for hiring a woodworking machine operator in Canada can vary depending on location, experience, company size, and the specific woodworking tasks involved. However, a woodworking machine operator typically earns an annual salary of $37,050 (equal to $19 per hour), with novice operators earning $32,175 annually and more experienced ones making up to $46,410 per year.

The average wage for hiring a woodworking machine operator in Canada can vary from province to province. The following table shows the average wages in different provinces in Canada:

Province/Territory | Minimum Wage | Average Wage | Maximum Wage |

Alberta | $16.00 | $20.75 | $30.00 |

British Columbia | $18.50 | $22.50 | $35.00 |

Manitoba | $15.50 | $18.00 | $21.45 |

New Brunswick | $14.75 | $19.00 | $28.00 |

Newfoundland and Labrador | $16.27 | $17.47 | $21.11 |

Ontario | $17.85 | $20.00 | $28.00 |

Quebec | $15.25 | $19.00 | $26.00 |

Different Types of Woodworking machine Operators we Hire in Canada

In Canada, woodworking machine operators are hired for various roles that involve operating specialized machinery and equipment to shape, cut, and create wood products.

Here are some different types of woodworking machine operators that we commonly hire:

CNC Router Operator

CNC (Computer Numerical Control) router operators work with computer-controlled routers to cut and shape wood based on specific designs and patterns. They program the machine and oversee its operation to create precise and intricate woodwork.

Saw Operator

Saw operators operate different types of saws, such as table, circular, and band saws. They are responsible for making accurate cuts in wood according to specifications for various woodworking projects.

Planer and Jointer Operator

Planer and jointer operators work with planers and jointers to smooth and shape rough wood surfaces, ensuring uniform thickness and smooth edges for further processing.

Lathe Operator

Lathe operators use wood lathes to create cylindrical or rounded shapes in wood. They may craft items like chair legs, spindles, or decorative wood pieces.

Moulder Operator

Moulder operators work with moulders to create profiles and shapes on wooden pieces, such as trim, mouldings, and architectural components.

Edgebander Operator

Edgebander operators use edgebanding machines to apply edge banding materials to the edges of wood panels, enhancing their appearance and durability.

Router Operator

Router operators use handheld or table-mounted routers to hollow out or shape wood pieces, creating decorative edges, grooves, and designs.

Boring Machine Operator

Boring machine operators use specialized machines to create holes, dowel connections, and insets in wood pieces, contributing to the assembly of larger structures.

Sanding Machine Operator

Sanding machine operators work with sanders to smooth and finish wooden surfaces, ensuring a polished appearance before finishing.

Laminating Machine Operator

Laminating machine operators use laminators to bond layers of wood or wood veneer, producing panels with enhanced strength, appearance, or texture.

Veneer Machine Operator

Veneer machine operators handle machines that cut, slice, or peel thin layers of wood veneer for various woodworking applications.

Wood Carver

Wood carvers specialize in intricate carving and shaping of wood to create detailed and artistic designs on furniture, sculptures, and decorative items.

Machining Center Operator

Machining center operators handle advanced woodworking machinery, such as CNC machining centers, capable of performing multiple operations like drilling, milling, and routing in a single setup.

Takeaway

Adept woodworking machine operators play a crucial role in establishing the efficiency and quality of your woodworking business. Whether operating a large-scale workshop or specialized studio, you can rely on Hookjobs to seamlessly connect you with talented operators who meet production needs and uphold your exacting standards. We take pride in identifying capable candidates who excel in their roles, significantly contributing to improved productivity and delivering high-quality products.

FAQs

Q1. Are woodworking machine operators in demand in Canada?

A: Yes, woodworking machine operators are in demand in Canada, particularly in industries related to construction, furniture manufacturing, and woodworking. The demand may vary by region and economic conditions, but skilled operators are often sought after to contribute to various woodworking projects.

Q2. How many hours do woodworking machine operators usually work in Canada?

A: Woodworking machine operators typically work full-time hours, which can vary depending on the specific industry and employer. They commonly work standard weekday shifts, but overtime or irregular hours might be required during peak production periods.

Q3. Should I provide the woodworking machine operators with the necessary tools?

A: Providing necessary tools and equipment is a common practice, but it varies by employer. Some woodworking businesses provide specialized tools and machinery, while others may require operators to bring their basic hand tools. Clearly communicate expectations regarding tool ownership during the hiring process.

Q4. What safety precautions should woodworking machine operators take?

A: Woodworking machine operators should prioritize safety by wearing appropriate personal protective equipment, adhering to safety guidelines and protocols, keeping workspaces clean and organized, and receiving proper training on machine operation and emergency procedures.

Q5. Can I hire woodworking machine operators from other countries?

A: Yes, you can hire woodworking machine operators from other countries through the Labour Market Impact Assessment (LMIA) process. An LMIA is required to demonstrate that hiring a foreign worker will not negatively impact Canadian job opportunities.

Q6. What insurance coverage should I consider when hiring woodworking machine operators?

A: Consider liability insurance, workers’ compensation coverage, and equipment insurance to protect the woodworking machine operators and your business.

Q7. What role does technology play in the work of carpentry?

A: Technology has significantly impacted woodworking, with advanced machinery, computer-controlled tools, and design software enhancing precision, efficiency, and creativity. Woodworking machine operators must adapt to technological advancements to remain competitive and productive.

Q8. What are the benefits of hiring woodworking machine operators through a recruitment agency?

A: Hiring woodworking machine operators through a recruitment agency offers access to a pool of pre-screened and qualified candidates, saves time in the hiring process, and leverages the agency’s expertise in matching skills and qualifications to your business needs.

Q9. How can woodworking machine operators stay updated with industry trends and techniques?

A: Woodworking machine operators can stay updated by attending industry workshops, participating in trade associations, reading woodworking publications, and engaging with online forums. Continuous learning helps them adapt to new technologies and techniques in the field.

Q10. What is the minimum age for hiring a woodworking machine operator in Canada?

A: In Canada, the minimum working age for most provinces and territories is generally 15 or 16 years old. However, there are specific regulations and restrictions regarding the types of tasks, work hours, and conditions for young workers.